PRODUCTS

The company’s products are widely applied to industries including agriculture, foodstuff, toys, stationery, transportation, etc. The products with a variety of shapes and sizes can satisfy different requirement. More importantly, the raw materials that are non-toxic and environmental-friendly, comply with international safety standard.

-

1

Farm product packaging

Farm product packaging is an important selling point for marketing vegetable or fruit. Exquisite patterns make product more prominent than other similar products

-

2

Roll film

Film rolls are not only extensively used to automatic packaging equipment to heat-seal hard plastic product but also used to package goods .

-

4

Food package

Food package is a very broad category, and generally it is commonly seen to package food for sale.

-

5

File bag

The file bags are used for the storage of daily working paper. Different dimensions and colors are available.

-

6

Transportation packages

Transportation packages aims to protect goods free from external damage during transport.

-

7

Liquid packing bags

Liquid packing bags have the advantages of foldability, crashworthiness, easiness in transport, high barrier, etc. This kind of bags are widely used to package liquid products

-

8

Biodegradable packing

Biodegradable packing bags are the trend at present. The packing bags made of by biodegradable materials can relieve the stress of current plastic pollution because this type of bags can completely degrade in landfill within several months, and do not do harm to environment and creature.

-

8

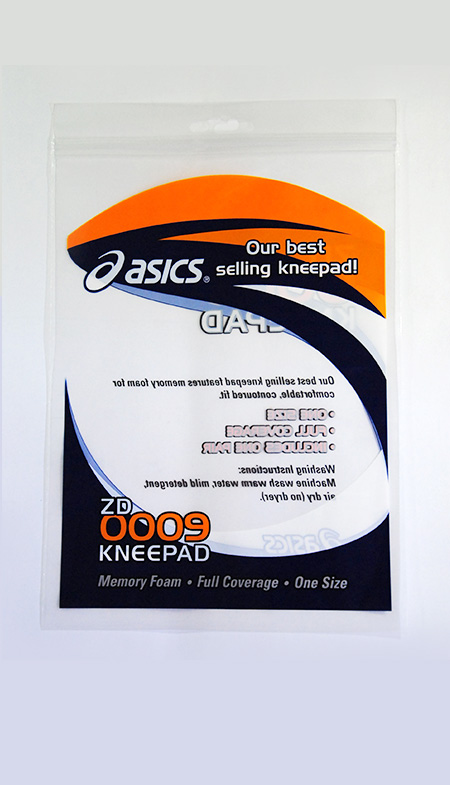

Toy / gift bag

his kind of bags are mainly used for toy packaging and gift packaging, which require nice workmanship, well-printed content and excellent material.

ABOUT US

Dongguan Shunbang Plastic & Hardware Co., Ltd., founded in 2006, is located in Changshantou Industrial Zone, Qingxi Town, Dongguan City, which owns 10,000 square meters of modern dust-free clean plants and has more than 100 employees.

-

Company Profile

Dongguan Shunbang Plastic and Hardware Co., Ltd. (Hereinafter referred to as “Shunbang Company”) is a private enterprise, with the address at Changshantou Industrial Area of Qingxi Town, Dongguan City.

-

Culture

The Company upholds to the management philosophy of ”Scientific Management, Innovative Exploitation, Sustainable Development and Continuous Improvement.”

NEWS

Quickly learn about the latest news and industry news

CONTACT

If you have any needs or suggestions for our products and services, you can call us at 0769-87281558 or leave us a message online.

粤ICP备11083815号 Powered by www.300.cn